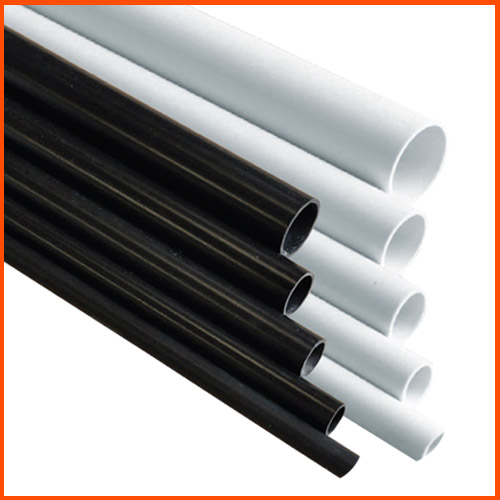

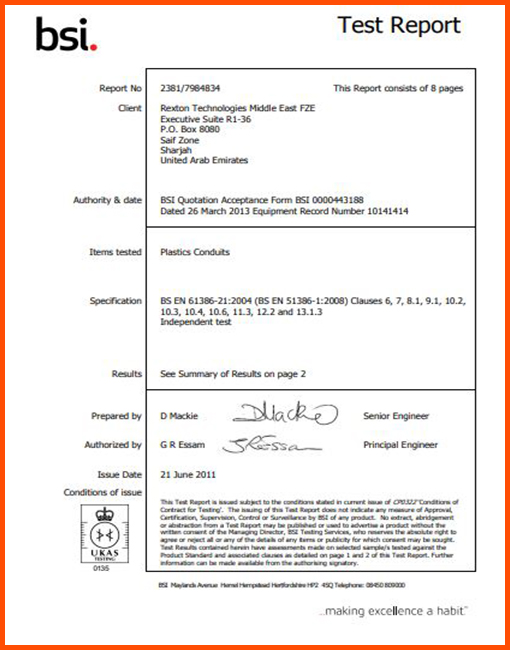

Rexton PVC conduits, conduit accessories, adaptable boxes, flexible conduits, PVC flush and surface boxes are made in the Plastic processing Plant Located in the Sai zone Sharjah. The Plant is fitted with High speed German extruders, which extrudes 450 kilometersof PVC electrical conduit pipes daily. The high-quality electrical pipes made from Virgin Plastics withstands the stringent test of all International standards and complies to all International standards. The Pipes are tested to BS 4670 and IEC.

REXTON is the flagship brand of Kingston Holdings. The PVC manufacturing plant extrudes 176 million meters of electrical conduit pipes and 73million pieces of metal back boxes under REXTON brand annually. The manufacturing plant, located in the middle of an environmentally friendly backdrop abundantly blessed with thick greenery, contributes substantially in reducing carbon footprint. REXTON products are widely used in all major projects in the UAE and GCC countries and are also exported to the UK, Europe and all African countries and the subcontinent.

The product range includes electrical conduits and accessories, PVC surface and flush boxes, dry lining boxes, adaptable boxes, electrical wiring accessories (switches & sockets, plug tops, plug in type and normal ceiling roses, batten and pendant holders, extension sockets, domestic and commercial LED light fittings, street lights, weather and water proof isolating switches, metal back boxes, networking cabinets and power distribution enclosures (IP and non IP rated).

PVC conduits and accessories are manufactured from virgin plastics supplied by world’s largest plastic raw material manufacturers. High speed German machines, fitted with ultramodern control devices, ensure defect-free processes and extrudes all sizes of pipes which can withstand the test of any stringent specified standards with zero failure. Fully automatic mixing plants ensure proper mixing of raw materials and other ingredients with zero manual inputs controls a totally defect-free compound which is automatically fed into the extruders which provide a dust-free clean environment inside the factory premises. The plants have adopted the most efficient quality control methods, using scientific tools like balance score cards, and set defects monitoring and tracking methods like PPM monitoring to ensure quality of incoming raw materials and finished products. These stringent methods followed by the QC team ensure defect-free products suitable for any large projects.

Rexton PVC conduits, conduit accessories, adaptable boxes, flexible conduits, PVC flush and surface boxes are made in the Plastic processing Plant Located in the Sai zone Sharjah. The Plant is fitted with High speed German extruders, which extrudes 450 kilometersof PVC electrical conduit pipes daily. The high-quality electrical pipes made from Virgin Plastics withstands the stringent test of all International standards and complies to all International standards. The Pipes are tested to BS 4670 and IEC.

Rexton PVC conduits, conduit accessories, adaptable boxes, flexible conduits, PVC flush and surface boxes are made in the Plastic processing Plant Located in the Sai zone Sharjah. The Plant is fitted with High speed German extruders, which extrudes 450 kilometersof PVC electrical conduit pipes daily. The high-quality electrical pipes made from Virgin Plastics withstands the stringent test of all International standards and complies to all International standards. The Pipes are tested to BS 4670 and IEC

Rexton PVC conduits, conduit accessories, adaptable boxes, flexible conduits, PVC flush and surface boxes are made in the Plastic processing Plant Located in the Sai zone Sharjah. The Plant is fitted with High speed German extruders, which extrudes 450 kilometersof PVC electrical conduit pipes daily. The high-quality electrical pipes made from Virgin Plastics withstands the stringent test of all International standards and complies to all International standards. The Pipes are tested to BS 4670 and IEC.

Rexton PVC conduits, conduit accessories, adaptable boxes, flexible conduits, PVC flush and surface boxes are made in the Plastic processing Plant Located in the Sai zone Sharjah. The Plant is fitted with High speed German extruders, which extrudes 450 kilometersof PVC electrical conduit pipes daily. The high-quality electrical pipes made from Virgin Plastics withstands the stringent test of all International standards and complies to all International standards. The Pipes are tested to BS 4670 and IEC.

Rexton in its PVC plant manufactures high quality Drylining boxes.